DESIGN

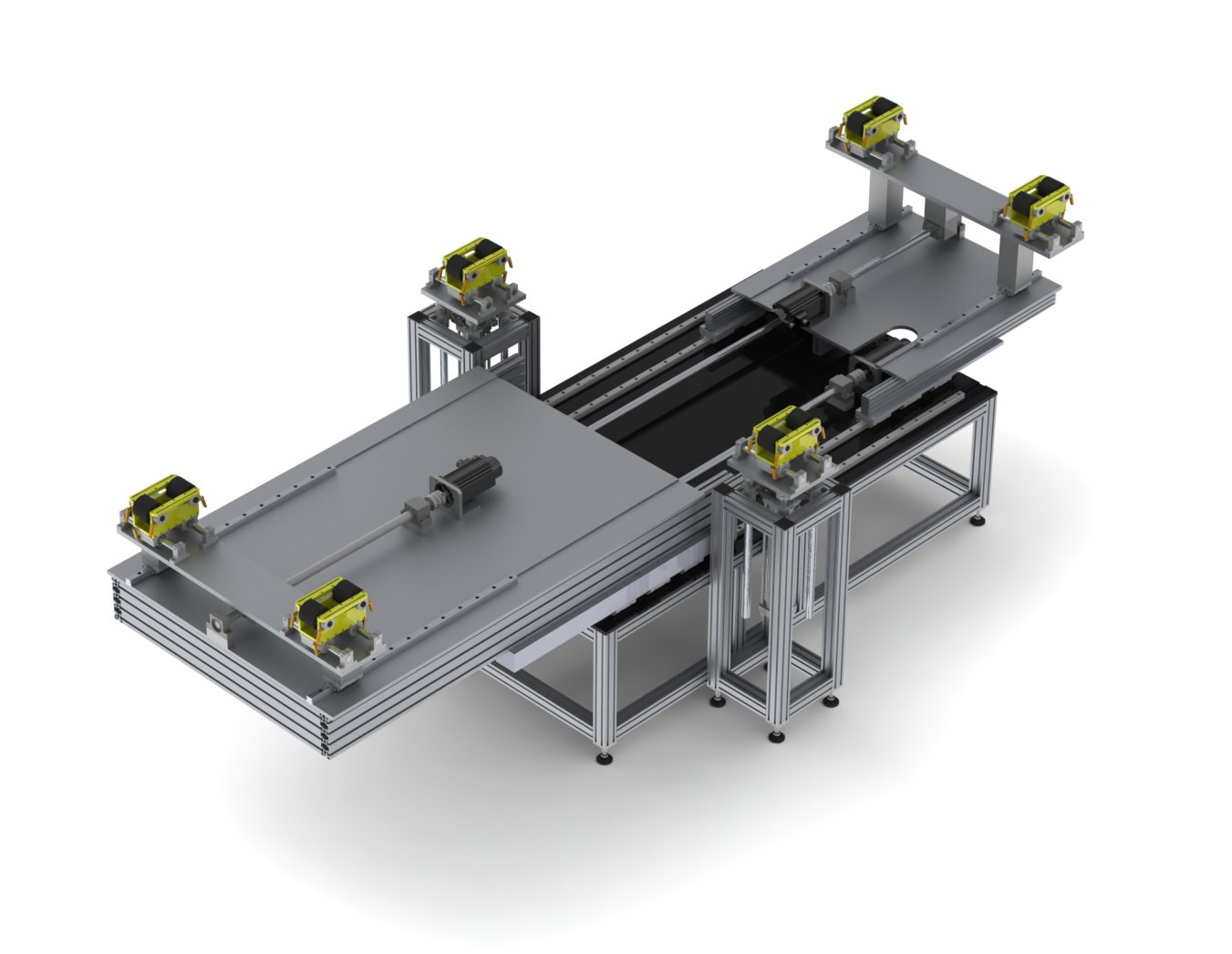

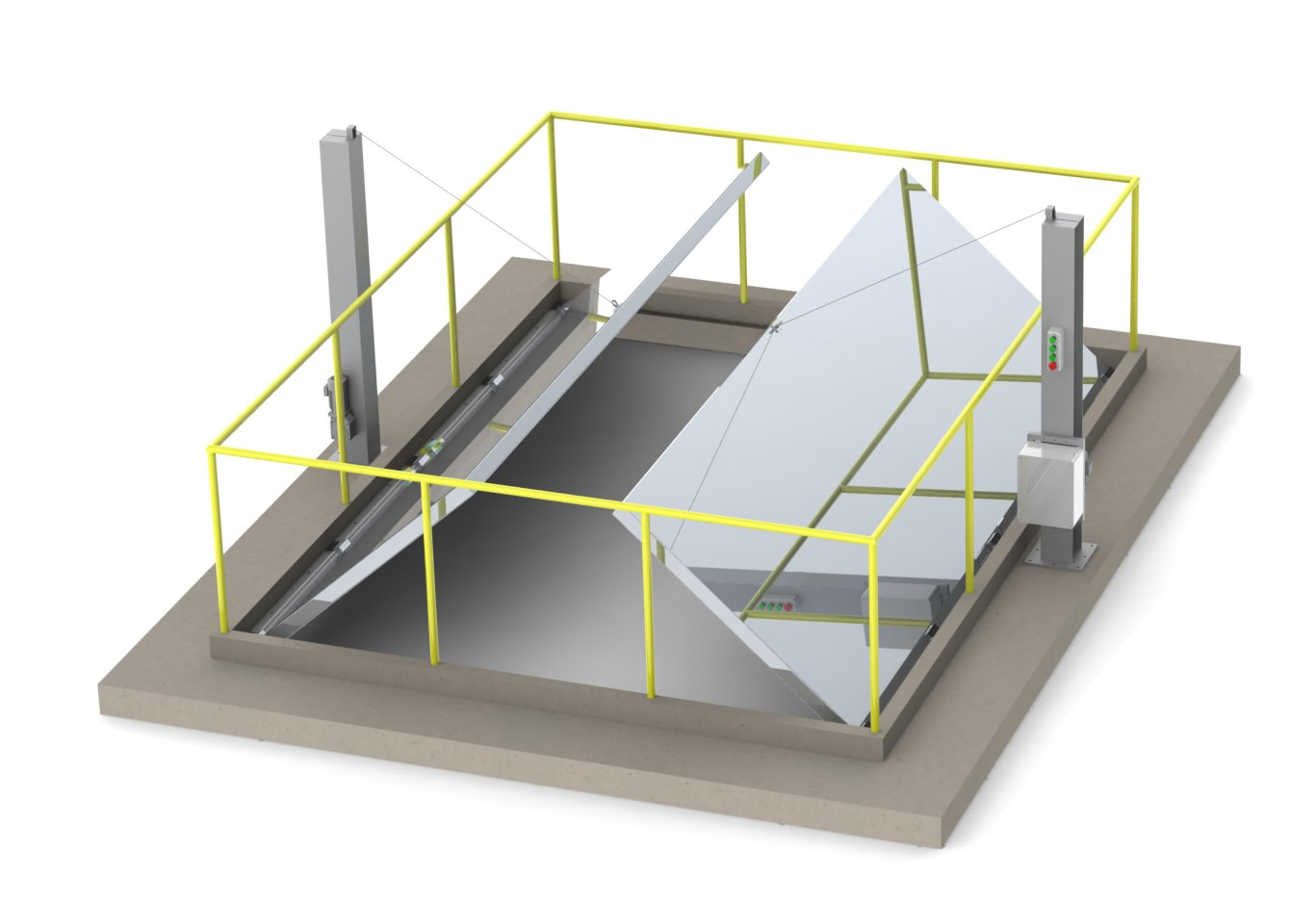

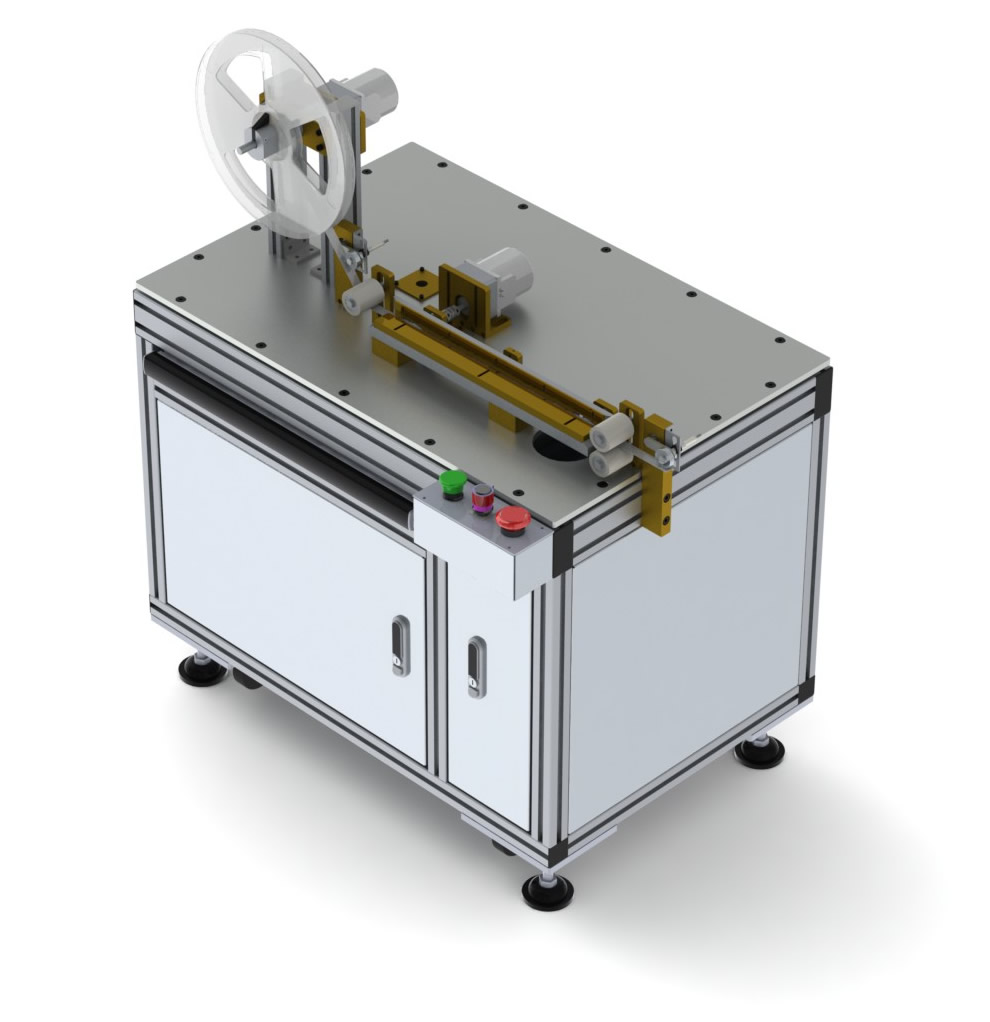

Name: Electronics Part Quality Control Machine [designed & fabricated for Generex Technology Co., Ltd.]

Key function: The electronics part is automatically fed to the machine and the quality control process is performed continuously. When defected parts are detected, the signal light will show up.

Key design: The mechanical system is seamlessly designed to the vision system, i.e., high definition industrial camera, which is essential for the quality control process. The Electronics Part Quality Control Machine is operated under the Programmable Logic Controller (PLC) that is reliable and used by many industries and machines.